Working with Dielines

This article is Number 10 of the Packaging Made Simple blog series, inspired by the principles outlined in my Amazon bestselling book Your Amazing Itty Bitty™ Guide to Packaging Made Simple. Each post dives deeper into the topics from the book, offering actionable insights and practical tips to help you create packaging that not only looks great but also works seamlessly for your brand and customers.

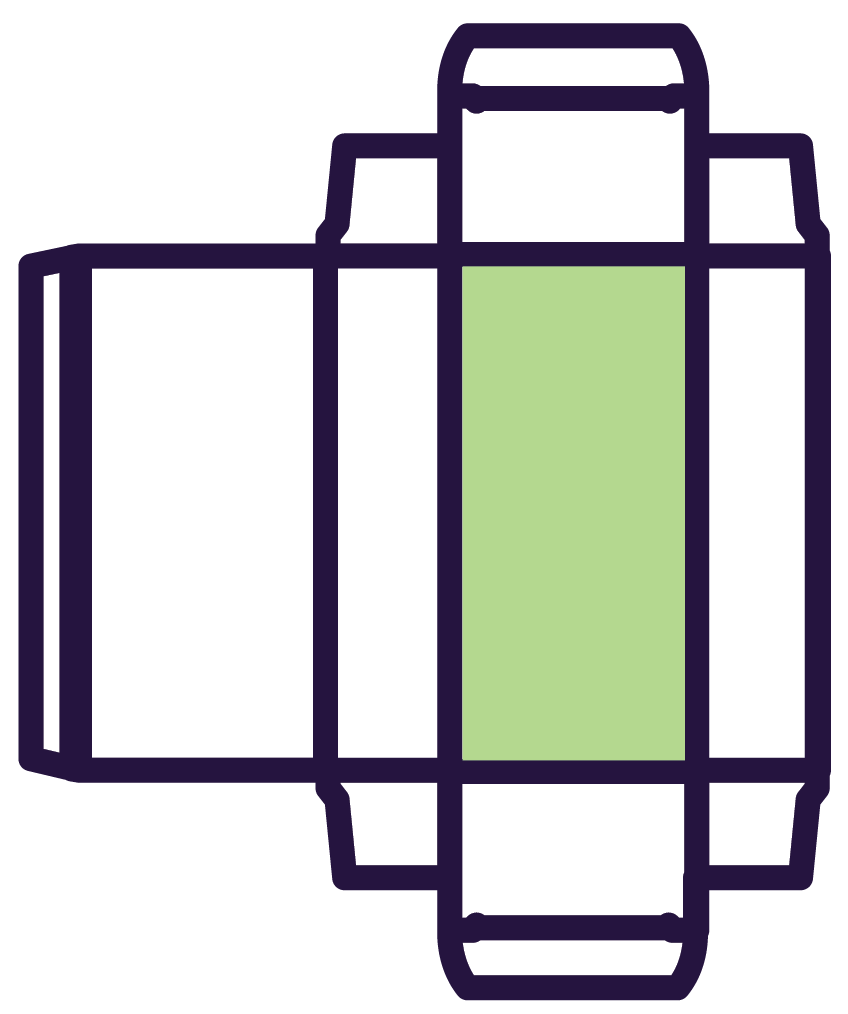

When it comes to creating packaging, a dieline is one of the most essential tools you’ll encounter. Think of a dieline as the blueprint for your packaging design—it outlines where your packaging will be cut, folded, and glued, ensuring the final product comes together exactly as intended. Without a properly prepared dieline, even the most beautiful designs can fall apart during production.

Understanding dielines is a critical step in bringing your packaging to life. By learning how they work and collaborating effectively with your supplier, you can avoid costly errors, streamline the production process, and ensure your packaging performs as intended.

What is a Dieline?

A dieline is a flat, technical template that shows the exact layout of your packaging. It includes markings for folds, cuts, glue areas, and any additional features like perforations or windows. Dielines are used in the production of all types of packaging, from folding cartons and labels to shipping boxes and flexible pouches.

The dieline serves as the foundation for your artwork, ensuring that your design fits perfectly on the final structure. It’s created by packaging engineers or suppliers who understand the machinery and tolerances needed to produce your packaging. For example, the dieline for a retail box will indicate not only its size and shape but also how it will be assembled, whether by hand or machine.

The Importance of Using the Right Dieline

While it may be tempting to create your own dieline, it’s always best to use the one provided by your supplier. Suppliers design dielines to match the capabilities of their equipment, ensuring that the finished product is accurate and consistent. Using a dieline from another source—or making unauthorized changes to a supplier’s dieline—can lead to misalignment, poor folds, or even rejected production runs.

Once you receive your supplier’s dieline, it’s important to review it carefully before adding your artwork. Check the dimensions, confirm the placement of folds and cuts, and make sure the structure aligns with your design intentions. This extra attention to detail at the outset can save significant time and money during production.

The Dieline Process: From Concept to Production

The dieline process typically starts after you’ve finalized the structure of your packaging. Your supplier will create a dieline based on the approved structure and share it with you or your design team. At this stage, you’ll receive a “white sample”—a prototype of the packaging without any printing—to confirm the physical fit and functionality.

Once the dieline is approved, your designer or production artist will place your artwork onto it, ensuring that all elements align with the template. This includes making sure important details, like logos and text, don’t fall into fold or cut areas. After the artwork is finalized, the dieline is sent back to the supplier for proofing and production.

It’s crucial to avoid making changes to the dieline yourself. If adjustments are needed, they should always be made by the supplier to ensure the final product is compatible with their machinery.

Best Practices for Working with Dielines

To get the best results from your dieline, keep these best practices in mind:

Always request the dieline from your supplier after the white sample has been approved. This ensures the template matches the structure you’ve signed off on.

Use professional design software like Adobe Illustrator to place your artwork onto the dieline. This software is industry-standard and provides the precision needed for packaging production.

Provide a PDF proof of your artwork to your team and stakeholders for review. While not a substitute for physical proofs, PDFs can help catch layout errors early.

Communicate with your supplier throughout the process. If you’re unsure about any aspect of the dieline or need guidance, don’t hesitate to ask.

Conclusion:

Dielines are the unsung heroes of packaging production. They provide the roadmap for transforming your creative designs into functional, professional packaging. By understanding how dielines work and collaborating closely with your supplier, you can ensure a smooth transition from concept to production and avoid costly mistakes. A well-prepared dieline is the foundation of packaging success.

Ready to master the dieline process? Join our upcoming workshop, where we’ll walk you through creating and using dielines effectively, ensuring your packaging designs translate seamlessly into production.